YKK was founded in Japan as a zipper manufacturing company in 1934 by Tadao (pronounced in English as Tah-dah-o) Yoshida. In the early years, Mr. Yoshida’s company carried his name; it was called Yoshida Kogyo Kabushikikaisha–or “YKK” for short. (That long Japanese name translates roughly into English as “Yoshida Company Limited.”) Over the years, the letters “YKK” were stamped onto the zippers’ pullers, and thus YKK became known as the Company’s trademark.

FAQs

General Information about YKK

Other than zippers, what other products does YKK produce today?

Aside from zippers, YKK also makes other fastening products–like hook & loop self-closing tape fastening systems, webbings, snaps, buttons, metal and plastic notions and buckles. YKK AP produces aluminum building products — like window and entrance systems for low, medium and high rise applications, as well as vinyl windows and doors for homes.

YKK has a famous philosophy: what exactly is it?

Mr. Yoshida called his philosophy the CYCLE OF GOODNESS®. It means that “No one prospers without rendering benefit to others.” According to his philosophy, Mr. Yoshida believed he must manufacture only useful, high quality zippers that would benefit, or enhance, the end-use goods in which they were installed. Since his product was a component in his customers’ products, and the critical moving part, he believed it would have to perform perfectly over a long period of time so that those end-use goods would last longer and perform better than others on the market. When they did, all involved would benefit. Because of this guiding principle, YKK became involved in vertical manufacturing. This means that YKK not only produces the zippers, but also the machines that make the zippers–and even many of the raw materials that go into the zippers–like the polyester and brass that make up the tape, teeth and sliders. Learn more about YKK’s corporate philosophy.

How large is YKK? Where is YKK Headquarters?

Today, YKK Corporation has 106 affiliated companies in 72 countries/regions around the world. Here is a list of all YKK global locations.

The worldwide parent company, still privately held, is YKK Corporation with headquarters in Japan. Administrative headquarters are in Tokyo, and manufacturing headquarters are located where the company was originally founded, in Kurobe, on the far side of the big island of Japan. The YKK Americas Group headquarters is YKK Corporation of America, located in Atlanta, Georgia.

Where can I find YKK® products?

Please contact YKK so we can help you find the best product(s) for your application.

Does YKK have an environmental policy?

Yes, in 1994 YKK established a YKK Group Environmental Charter for our organization worldwide. The basic principle of this Charter is to seek harmonization between abundant and healthy lives for all humankind and the environment. Under this Charter, YKK will endeavor to preserve and improve the environment in all aspects of our business activities. The YKK Group established the YKK Group Environmental Charter in September 1994, and has consistently taken on environmental issues as a company-wide challenge. The principle of the Environmental Charter is to promote prosperous, healthy lives and harmonious co-existence with our environment, and to preserve and improve the environment throughout our corporate operations. Through our corporate activities, we seek to develop an environmentally friendly management style and contribute to the establishment of a recycle-type economic society by promoting environmental policies at all stages, from design and production to disposal, collection, and recycling.

Additionally, YKK (U.S.A.) Inc. pledges to:

Eliminate Waste — YKK will work to find better ways to manufacture our products with less toxic materials and feed-stocks thus reducing or eliminating the generation of waste.

Prevent Pollution — YKK will develop and maintain pollution prevention plans that focus on minimizing waste at the source and comply with all relevant environmental legislation, regulations, and other requirements to which YKK subscribes.

Continually Improve — YKK will work diligently continually to improve the Environmental Management System (EMS) to lessen our environmental impact.

Provide Resources — YKK will provide the necessary resources and information to develop, implement, and maintain an effective EMS.

Provide Information — YKK will make the policy available to all employees and the public to provide a better understanding of YKK’s environmental commitment to the three Rs: Reduce, Recycle, Reuse.

Does the YKK Americas Group have a mission statement? What is it?

As employees in the companies which comprise the YKK Americas Group, we take great pride in our mission which is to innovate, produce, sell and service quality closures and architectural building products so that we might render benefit to society in the following ways:

Customers — by providing superior products that best meet their needs in the changing global marketplace — the components and technology which add value to their products, thereby contributing to their profitability and growth. Our trading partners also include suppliers, bankers, and other professionals. We value our relationships with them, and we will always treat them fairly.

Employees — by providing a safe and secure workplace, a respectable livelihood, and challenging opportunities to develop potential to the fullest. By welcoming and respecting different cultures and personalities within our company we become stronger. We are all “YKK Citizens.”

Communities — by providing jobs, paying taxes, and utilizing local businesses. Through our individual and corporate participation, we will actively support the communities in which we work and live. As good corporate citizens, we will promote technological development and comprehensive measures to preserve and enhance the environment.

To achieve these goals, we must ensure that our company remains financially sound. Accomplishing this will require teamwork, flexibility, continuous improvement of our individual efforts, and strong, skillful leadership throughout YKK Americas Group. The results will benefit all society as we work, grow, and prosper together.

How can I purchase stock in the YKK Company, and what's your trading symbol on the NY Stock Exchange?

YKK is a privately held company. Our stock is not for sale, and we therefore have no trading symbol. We appreciate your interest in YKK.

Does YKK offer manufacturing equipment?

YES! Our department known as the Field Technology Center (or FTC for short) opened its doors back in 1978 to establish YKK as a total solutions provider! Learn about YKK’s Field Technology Centers.

Information about Zippers and Sliders

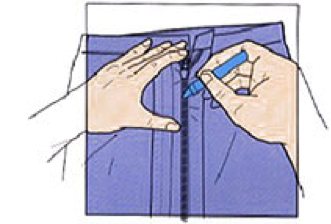

The slider does not open or close smoothly.

The elements’ gears can be damaged by forcing a slider that does not open or close smoothly. Apply paraffin or the ZIPPYCOOL® lubricating spray to the front and back side of the elements and move the slider up and down several times to work in the lubricant and make the slider work smoothly.

Are zipper quality and function of an equal standard globally?

All the zippers produced and sold throughout the world by YKK meet the quality standards set by YKK, so there is no difference in quality and function. However, special care should be taken regarding the existence of counterfeit zippers. Click to learn more about YKK’s brand protection activities.

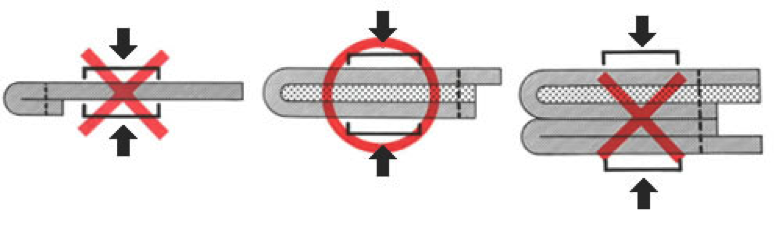

How do I attach a YKK® Zipper?

The proper way to attach a YKK® zipper depends on the specific application, so please consult your YKK sales representative to discuss attachment methods for your specific application.

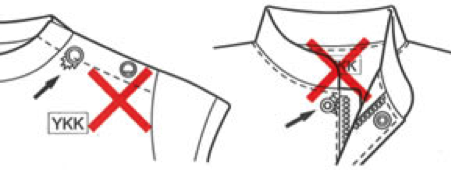

Please see pages 60-65 of our fastening catalog for precautions for zipper sewing.

A zipper made of or coated with nickel caused an allergic reaction upon direct contact with skin. How can I avoid this?

When a silver-colored metal zipper is required, choose an aluminum zipper. We offer a variety of products which meet European Nickel Directive (now part of REACH). Please ask your YKK representative for “N-ANTI” or “anti-nickel” products.

Do YKK products contain lead?

Except for a few specialized items, the lead content levels of YKK products meet the following regulations & standards: CPSIA, EN71-3, and OEKO-TEX® Standard Class I. See “Laws & Regulations” for details.

Are YKK products treated for needle detection machines?

YKK has researched and developed materials, surface treatments, strengths, and zipper designs to prevent false needle detection.

I have a problem with a metal zipper changing color.

There are various types of problems with metal zipper discoloration. Please see the YKK Zipper Instruction Manual pages below for details:

“2-2 Change in Metal Zipper Color caused by Garment Dye Treatment”

“2-3 Change in Metal Zipper Color caused by Bleaching”

“3-2 Change In Metal Zipper Color caused by Leather Products”

“3-3 Change In Metal Zipper Color caused by Wool Products”

How can I avoid safety issues caused by the protruding edges of coil zipper elements?

Please see “4-1 Proper Sewing of Coil Zippers” on page 31 of the YKK Zipper Instruction Manual for avoiding coil zipper sharp edge problems.

Why does paint often come off of a slider after dry cleaning/washing?

Please see “2-8 Slider Paint Chip Off” on page 21 of the YKK Zipper Instruction Manual for the information on slider paint chip-off.

I am an individual consumer, and my zipper broke! How can I find a replacement?

YKK manufactures millions of zippers a day for sale to our customers who produce consumer goods like jeans, tents, luggage, sporting goods, etc. We are not set up to sell one zipper to an individual. Instead, American & Efird, the thread company, serves the home sewing market for us. Contact American & Efird and someone will provide you with the retailer nearest to you who carries YKK® zippers. We appreciate your interest in YKK.

What's the difference between water-resistant vs. waterproof zippers?

One of the most common misunderstandings regarding our water protective zipper product offerings is the difference between water-resistant and waterproof. These terms are often used interchangeably in conversation by both our customers and the industry in general. It is not until you understand YKK’s water protective product offerings that you begin to realize the extreme differences in these terms.

Understanding the Difference Between Water Resistant and Waterproof Zippers

What is the difference between pin lock sliders and auto lock sliders?

Auto Lock sliders have a small locking mechanism in it that keeps the slider in place unless the slider’s tab is pulled, which releases the locking mechanism. Pin Lock sliders are locked in place when the pins on the puller are pushed down into the elements of the zipper.

Pin Lock vs. Auto Lock Sliders: Understanding the Differences

What is a Sustainable Zipper?

This is a question that more customers are asking as they seek to find ways to reduce the environmental footprint of their products. While the term “sustainable” would seem to be straightforward and easy to understand, it can be tricky as it has different meanings for different people. At YKK, we define “sustainable” as products that use input materials or production processes that utilize less energy and water, use no toxic chemicals, and emit fewer greenhouse gas emissions compared to conventional zippers.

Information about Snaps and Buttons

What is the best foundation for attaching snap fasteners?

The best foundation is two plies of fabric plus one ply of interlining.

Why do we need an interlining sewn to fabric when attaching snap fasteners?

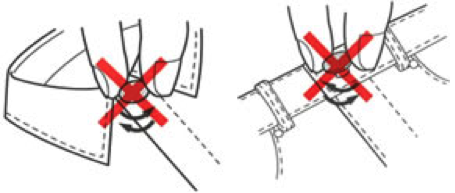

If the interlining is not sewn to the base fabric, the fabric around the snap fasteners may tear after several ON/OFF usages. Make sure that the interlining and fabric are stitched together, especially on the back placket.

Can snap fasteners be attached to an uneven thickness?

Attachment to an uneven thickness may result in snap fasteners detachment, weak ON/OFF actions, or fabric tearing. Snaps cannot be attached to significant uneven thicknesses.

How can I prevent a snap fastener from turning around after it is attached to a thin piece of fabric?

A snap fastener may turn around if the fabric is too thin at the attaching point. Packing is required in this case.

How can I check to make sure that the snap fasteners attached to a piece of fabric will not come off easily?

Try to pluck the snap fasteners off with your fingertip or nail. Make this practice your routine at the beginning of your day’s work.

How can I avoid fabric tearing during snap fastener attachment?

Make sure you attach the snap fastener to the inside of the stitch line.

Is it okay to iron snap fasteners or place then in a high-temperature dryer machine?

Do not iron directly over snap fasteners. Ironing directly over snap fasteners may cause the metallic snaps to become scratched or deformed and the plastic snaps to become broken or distorted. Place a cloth over the snap fasteners before ironing on them.

Plastic snaps placed in a high temperature drying machine are less resistant to deformation, discoloration, and scratching.

What is a needle detector? How do I clean it?

A Needle Detector is a piece of equipment which is sensitive to ferromagnetic substances and which detects broken needle chips or other undesirable objects inadvertently contained in the garments. Garment accessories are made to be needle-detector proof so that they will not be confused with broken needle chips and other undesirable objects.

Keep the belt surface clean at all times. Dust or stains may cause the equipment to malfunction.

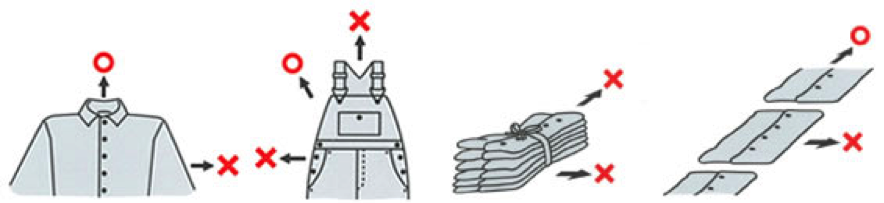

How should I place garments on the conveyor belt when using the Needle Detector?

The garments should be positioned so that their accessories enter the gate of the needle detector one at a time.

Is there a recommended pull-test machine?

An SafQ Snap Tester is recommended. It is used to determine the holding or breaking strength of prong-ring attached snap fasteners on garments. It consists of an upper snap clamp, a lower fabric clamp and force gauge mounted on a stand. The snap component is gripped by the upper snap clamp and the garment is fixed to the lower fabric clamp. By turning the top flywheel, the operator can apply a specific force and the holding force or the breaking strength can be recorded. Capability can be enhanced with clamps and accessories for the testing of other snaps, jeans buttons, four hole buttons and garment accessories such as zippers, bows, applique, toggles, hooks/bars, and D-rings, among others. Contact SDL Atlas Ltd. for more details.

Can YKK add customized logos to snaps, buttons, or burrs?

Yes. Contact us to learn more.

Information about Plastic Notions

Information about Hook and Loop

What is the best way to attach hook and loop fasteners?

A common misconception is that ANY hook and ANY loop configuration will work for a particular product or device. The fact of the matter is that deciding what hook and loop configuration to best fit into a product is much more complex. Directionality plays a major role in fastener performance and ultimately final product performance.

Learn the best way to attach hook and loop fasteners with YKK Americas

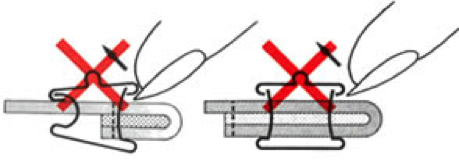

What is the best way to sew extruded plastic hook fasteners?

Considerations include sewing thread and stitch length as well as needle size in order to prevent tears.

Learn the best practices for sewing extruded plastic hook fasteners with YKK Americas

What is the difference between standard (napped or brushed) woven loop and unnapped woven loop?

Napped loop consists of woven fibers that are randomly disoriented, which allow for hooks of many types and good penetration, provides high peel and shear strengths, as well as excellent cycle life. Unnapped woven loop consists of a series of unbroken loops, which allow the loop to last longer over time and is used in applications which don’t require a high peel strength. This loop can provide a cycle life of over 20,000 and has a high quality “clean” appearance, as well as quick drying properties.

Learn more about the difference between napped and unnapped woven loop fasteners

How do I choose the right plastic hook and loop material?

There are a wide variety of extruded hook options that are engineered to engage with an assortment of woven, knitted, or nonwoven loop materials. These options allow customers to have just the right combination of peel, shear, and cycle life for their particular needs. The key is choosing the right combination.

Discover the key factors to consider when selecting plastic hook and loop material

Can all fasteners be welded together?

Welding YKK® fasteners to other materials depends on the material compatibility, the method used to weld them together, size of the weld, and the application.

Learn the best practices for welding YKK® fasteners